Débuted in 2013 and to commemorate the 25th anniversary of the “Express” rifle, German-born, custom rifle builder Ralf Martini was selected to redesign the stock and profile of the rifle. Reminiscent of best-grade English sporting rifles made “between the wars”, the “Express” rifle by Martini is a modern version of a classic design made with all the advantages of 21st century steel and CNC precision.

The HEYM “Express” is the most well-designed and well-built big-bore bolt action available today. HEYM goes to great lengths to ensure 100% reliability. No other maker builds cartridge-specific actions. No other maker builds cartridge-specific magazine boxes. Leaving no detail to chance, we manufacture our own barrels and all small parts for our “Express” rifles in-house.

| Barrel | 24" Krupp Steel, Hammer-Forged, In-House at HEYM |

|---|---|

| Action | Magnum, Mauser, Bolt Action with Controlled-Round Feed & Claw Extractor |

| Safety | 3-Position, Side-Swing |

| Trigger | Single-Stage, Set at a Crisp 3.5 lbs With no Creep and no Over-Travel |

| Magazine | 4 + 1 Capacity. Oberndorf-Style, Drop Box, One-Piece Construction with Straddle Floorplate & Trigger Bow Release |

| Stock | Select European Walnut (Upgrades Available) |

| Weight | 9.0 lbs - 10.5 lbs (varies with caliber) |

| Available Calibers | 375 H&H Mag, 416 Rigby, 404 Jeffery, 458 Lott, 450 Rigby |

HEYM’s cold hammer-forged barrels are renowned throughout Europe for their exceptional quality, precision and accuracy. In fact, of the roughly 6,000 barrels HEYM produces each year, 4,000 of those are sold to other gunmakers for use in their rifles. Starting with bar stock, we cut, drill, hone and rifle each barrel entirely in-house. This is the only way to ensure 100% quality control through every step of the process.

HEYM barrels do not require a break-in to remove tooling marks left from button and cut rifling processes. Thousands of pounds of pressure in the hammer-forging process mold the steel around a hardened mandrel forming a much smoother interior surface than either cut rifling or button rifling. Our forging process work-hardens the steel into a much more durable barrel and provides roughly 2x the barrel life of a button or cut rifled barrel without sacrificing uniformity or accuracy.

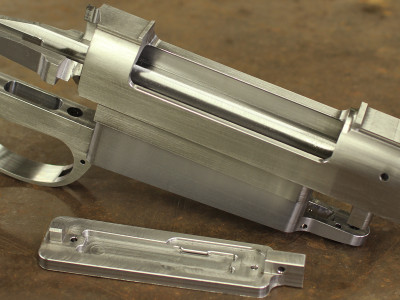

We don’t assemble our rifles from parts made by someone else. We design each part from the ground up and machine them ourselves from billets of steel.

Introduced in 1986, HEYM’s “Express” action is actually larger than a “Magnum” Mauser. Standard ’98 actions have a bolt diameter of .700," the Brevex was .750" and the HEYM is .785." This large action not only allows the HEYM “Express” to handle the largest of African calibers with ease, but also enables rifles to be built to the appropriate weight for caliber, while keeping the “weight between the hands.”

Each HEYM “Express” action is also made entirely in-house. Beginning with a solid billet of steel, the bore of the action and the raceways for the locking lugs are EDM wire cut. From this perfectly straight bore, the rest of the machining is completed. This ensures everything is perfectly square and parallel to the bore, which greatly contributes to the accuracy of the rifle.

A magazine box shaped for a specific cartridge is a solid foundation, but the action must also be made compatible with the exact cartridge to ensure absolute reliability. The bottom side of the action is where the cartridges transition from the magazine box into the chamber, and this is one of the most critical areas of proper cartridge feeding. Each “Express” action is machined for a specific cartridge. Rather than starting with parts and “gunsmithing” them together, we designed it correctly the first time, and there is no need to “gunsmith” an action into feeding.

To the untrained eye, it simply looks like cartridges in a magazine box, but a closer examination reveals a magazine box made specifically for a particular caliber of cartridge. Notice the walls on the inside of the magazine box perfectly form to the outside shape of the cartridge. This is no accident. Modifying a generic magazine box is not necessary when you have complete control over the production of each and every part of your rifle. HEYM is the only gunmaker in the world making cartridge-specific magazine boxes. They are the ultimate in reliability and feeding because starting with the correct geometry ensures that the cartridges feed correctly. This feature can be found nowhere else.

English-Style, Flat-top-Checkering is now available on the "Express," 88B and 89B as an option.

The recessed, two screw, rear swivel base is both functional and attractive (shown with optional case colors.)

The traditional ivory Night Sight provides a large front bead for fast sight acquisition in low-light conditions.

Shown here on our Model 89B Double Rifle, we also offer this feature on our Express Rifles.

Each caliber offered has a unique barrel contour that assures proper balance and weight distribution.